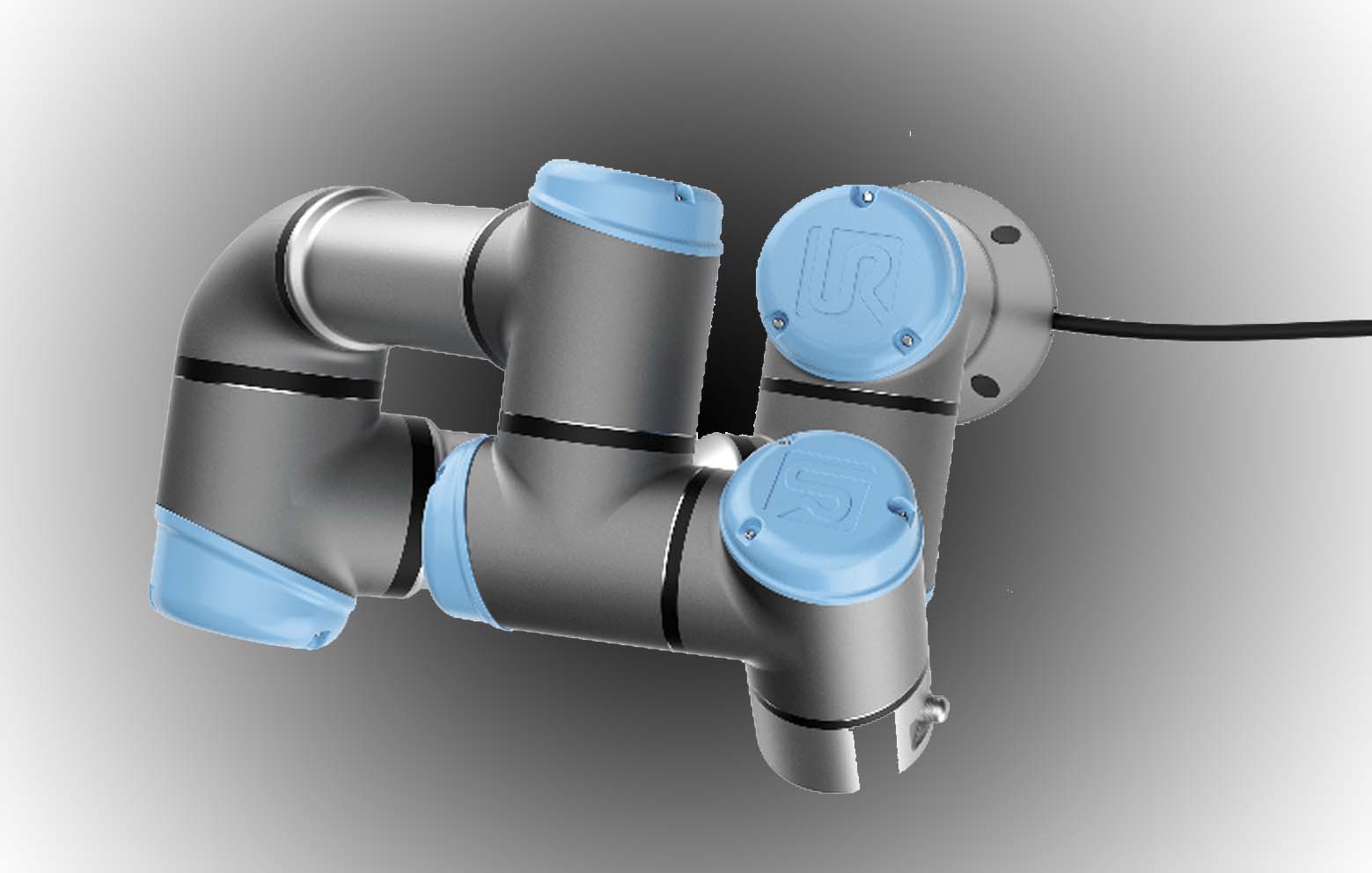

UR e-Series

Built with the future in mind, the e-Series is designed to grow in capability alongside businesses, taking on new tasks and finding new uses to be able to stay ahead of competitors. The e-Series takes robotic automation beyond what is possible today. Get set to trail blaze into the future.

- Description

- Specifications

EASY PROGRAMMING

A user friendly and intuitive teach pendant allow operators to program a cobot by moving its arms to the desired waypoints, or simply using drag-and-drop functions on a touchscreen tablet.

Even the most complex tasks can be taught to the cobot with Universal Robots’ Integrated Force Torque Sensor. Highly sensitive to even the slightest movements, the sensor enables the cobots to be programmed with precision for tasks where accuracy is of paramount importance.

FAST SET-UP

The cobots do not require special electrical installations and can be connected to any regular power outlet. An intuitive user interface enables easy set-up, installation and integration into the production line. Universal Robots+ products ensure hassle-free integration to maximize productivity by plug and produce.

FLEXIBLE

The cobots are lightweight, space saving and easy to re-deploy to multiple applications without changing production layouts. They can be moved between tasks quickly and are able to reuse programs for recurrent tasks, giving customers the flexibility to automate multiple manual tasks within one production facility even with just one cobot.

SAFE & COLLABORATIVE

The cobots are able to take over strenuous tasks in dangerous or dull environments. With the safety features, it is possible to fuse the best of human ingenuity with robot competency for accelerated productivity and growth.

FAST PAYBACK

Universal Robots makes robotic automation an option for small and medium enterprises, small batch production runs and other set-ups where traditional solutions may be too expensive.

APPLICATION

From the delicate handling of medical components to the large-scale assembly of bulky furniture, there is no task too difficult for the e-Series. Easily programmable, lightweight and compact, these cobots switch between tasks seamlessly and are economically viable even for the small-batch and mixed-product assembly lines.

- Built in force torque sensor

- 150+ Applications

- Light and responsive teach pendant

- Customizable stopping time and stopping distance

- Lesser implementation cost than traditional industrial robots

- Fast Setup

- Light weight

- Easy programming

- Flexible deployment

- Highly collaborative and safe

- Fastest Payback in industry

- Certified UR+ products for perfect robotic solution

- Easily replaceable joints

| UR 3 | UR 5 | UR 10 | UR 16 | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight | 11.2 Kg | 20.6 Kg | 33.5 Kg | 33.1 Kg | ||||||||||||||||||

| Payload | 3 Kg | 5 Kg | 10 Kg | 16 Kg | ||||||||||||||||||

| Reach | 500 mm | 850 mm | 1300 mm | 900 mm | ||||||||||||||||||

| F/T Sensor Force XYZ | ||||||||||||||||||||||

| Range | 10 N | 50 N | 100 N | 160 N | ||||||||||||||||||

| Resolution | 1 N | 2.5 N | 2 N | 5 N | ||||||||||||||||||

| Accuracy | 3.5 N | 4 N | 5.5 N | 5.5 N | ||||||||||||||||||

| F/T Sensor Torque XYZ | ||||||||||||||||||||||

| Range | 10 Nm | 10 Nm | 10 Nm | 10 Nm | ||||||||||||||||||

| Resolution | 0.02 mm | 0.04 mm | 0.02 mm | 0.02 mm | ||||||||||||||||||

| Accuracy | 0.1 Nm | 0.3 Nm | 0.6 Nm | 0.5 Nm | ||||||||||||||||||

| Joint Ranges | +/-360°; Infinite rotation on end joint | +/-360° | +/-360° | +/-360° | ||||||||||||||||||

| Joint Speed | All wrist joints: 360°/sec Other joints: 180°/sec | All joints: 180°/sec | Base & Shoulder: 120°/sec Elbow, Wrist 1, Wrist 2, Wrist 3: 180°/sec | Base & Shoulder: 120°/sec Elbow, Wrist 1, Wrist 2, Wrist 3: 180°/sec | ||||||||||||||||||

| Tool Speed | Tool: Typical 1m/s. (39.4 in/s) | All joints: 180°/sec | Tool: Typical 1m/s. (39.4 in/s) | Tool: Typical 1m/s. (39.4 in/s) | ||||||||||||||||||

| Repeatability | ± 0.03 mm | ± 0.05 mm | ||||||||||||||||||||

| Footprint | Ø128 mm | Ø149 mm | Ø190 mm | Ø190 mm | ||||||||||||||||||

| Degree of Freedom | 6 Rotating Joints | |||||||||||||||||||||

| Control box size (WxHxD) | 462 mm x 418 mm x 268 mm | |||||||||||||||||||||

| I/O Ports |

|

|||||||||||||||||||||

| I/O power supply | 24V 2A in control box and 12V / 24V 600mA in tool | |||||||||||||||||||||

| Communication | TCP/IP 100 Mbit: IEEE 802.3u, 100BASE-TX Ethernet socket & Modbus TCP in control box with 500Hz control frequency and RS485 in tool | |||||||||||||||||||||

| Programming | Polyscope graphical user interface on 12” touchscreen with mounting | |||||||||||||||||||||

| Noise | Comparatively noiseless | |||||||||||||||||||||

| IP Classification | IP54 | |||||||||||||||||||||

| Power Consumption | Approx. 100 watts | Approx. 200 watts | Approx. 350 watts | Approx. 350 watts | ||||||||||||||||||

| Collaboration Operation | All 17 advanced adjustable safety functions incl. elbow monitoring certified to Cat.3, PL d. Remote Control according to ISO 10218 Certifications by TUV Nord EN ISO 13849-1, Cat.3, PL d, and full EN ISO 10218-1 | |||||||||||||||||||||

| Materials | Aluminium, Plastic, Steel | |||||||||||||||||||||

| Temperature | The robot can work in a temperature range of 0-50° C* | |||||||||||||||||||||

| Power Supply | 100-240 VAC, 50-60 Hz | |||||||||||||||||||||

| Cabling | Cable between robot and control box (6 m) | |||||||||||||||||||||

| * At high continuous joint speed, ambient temperature is reduced | ||||||||||||||||||||||