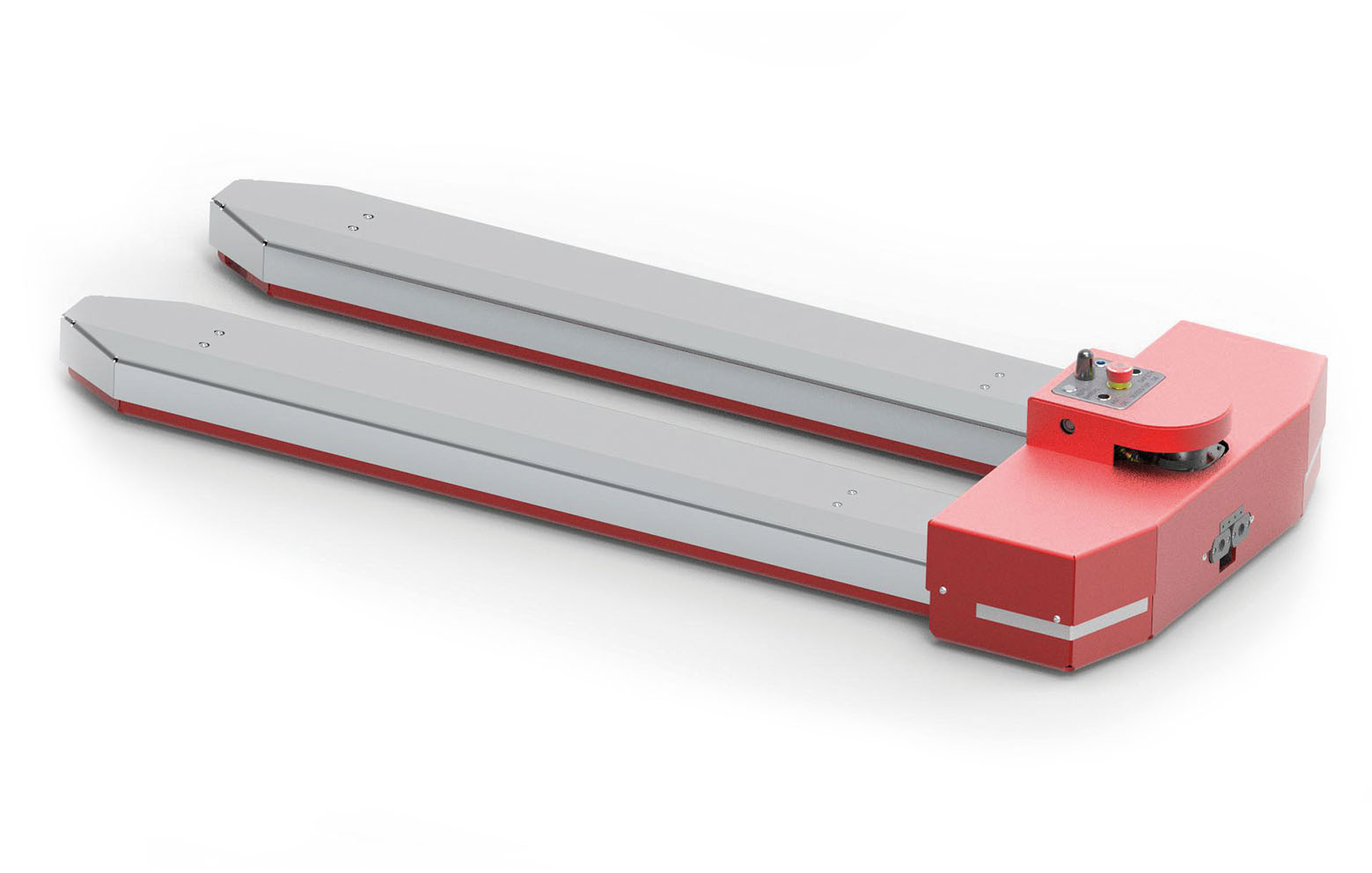

Karter Kompakt

The Karter Kompakt is a compact, low body, Autonomous Mobile Robot optimised for transporting pallets. It moves pallets weighing up to 1500 kg around your plant, efficiently and reliably.

Karters are compact, robust and agile. They work with your infrastructure and only need 10 minutes charging for an 8-hour shift. Navigation is autonomous, with convenient integration in your operations.

- Description

- Specifications

All Karters are based on a unified modular design and use the same navigation and management software, batteries and BMS. We can also design a unit fully tailored to your application.

Karters can travel around your plant to replace fixed conveyors, offering more flexibility while taking up less space. They can spin around their axis and operate in tight spaces.

Karters can operate on a regular schedule or ad hoc, collecting and delivering loads whenever required, anywhere in your warehouse and factory, to optimize internal logistics in many markets.

Karters only need 3 x 10 minutes to recharge when working around the clock. This makes them a perfect solution for industries with 24/7 operation or seasonal peak loads, where recruiting personnel can be challenging.

Effective Control

The control system communicates with a Karter over Wi-Fi when necessary, at the start and end of each trip. It then drives autonomously from the starting point to the destination.

Efficiency

Forklift drivers can be difficult to find and the work can lead to fatigue, mistakes and accidents. Karters provide an effective solution, working safely and efficiently around the clock.

Agility & Safety

Karters can turn on the spot, to operate in crowded buildings and narrow aisles. The safety laser scanners prevent collisions. Karters can cope with ramps, doors and lifts.

Battery

The Battery Management System (BMS) optimises the charging cycle and the life of the batteries. Our LiFePO4 batteries avoid the fire hazards of Li-ion batteries.

Integration

Karter software interfaces with a range of ERP and warehouse management systems. The Bluebotics platform is also used by other materials handling systems, facilitating integration of solutions from multiple suppliers.

Flexible Platform

All Karters are based on a modular design, using the same batteries, BMS, navigation and safety system. This platform is extended with model-specific features (lift, conveyor, etc.).

Safe Operation

Safety laser scanners at the front and back ensure Karters are safe to use close to personnel, other vehicles and unexpected obstructions. They provide navigation, based on the features of your building – no need to install cables in the floor or targets on the wall.

Configuration is straightforward and flexible: a Karter is driven around under manual control and scans the building to create a map. The map is then cleaned up and uploaded to the Karters. We provide on-site support for the system set-up.

Communication and Integration:

ANT® server is the advanced mission and fleet management software which also provides traffic control. It forms a bridge between the Karters, their web-based operator interface, external systems (ERP and warehouse management software), and external devices (automatic doors, bar code scanners, etc.). This software is developed by our partner Bluebotics, who have 20 years of experience in the field, and is easy to use. If your plant configuration or application changes your own personnel can reconfigure the system.

Karters use Wi-Fi for communications. We can advise you on the system requirements and security considerations.

- Safety

- Navigation

- Quick Charging (10 min)

- Plug & Play

- Flexible Deployment

- Robust

- Powerful

- Efficient Handling

- Hygienic & Easy to Clean

- Quick Reconfiguration

- Works Long Hours

Karter Kompakt

Weight: 120 kg

Maximum load: 1500 kg

Lifting stroke: 30 mm (option: 35 or 40 mm)

Option: external parts in stainless steel

General

Safety: safety laser scanner and safety software

Navigation: ANT® Autonomous Navigation Technology – natural feature navigation, based on mapping the working environment

Position accuracy: ± 1 cm

Speed: 2 km/h (standard), 4 km/h (option)

Turning radius: 0 m (turns around its axis)

CE-marked

Operation down to -25°C

Safety

Battery: LiFePO4, 24 V, 50 Ah, on-board Battery Management System (BMS)

Charging time: 10 minutes for 8 hours typical operation

Docking: automatic, controlled by the BMS

Larger battery packs: option on some Karter models