Pallet Conveyors

Pallet conveyor is a non-synchronous work-piece pallet based conveyor system designed to handle individual work-pieces. Typical components transferred on pallet conveyor would have a unique shape. Such conveyors are useful for moving products between equipment where they need to be present in a predefined orientation.

- Description

- Downloads

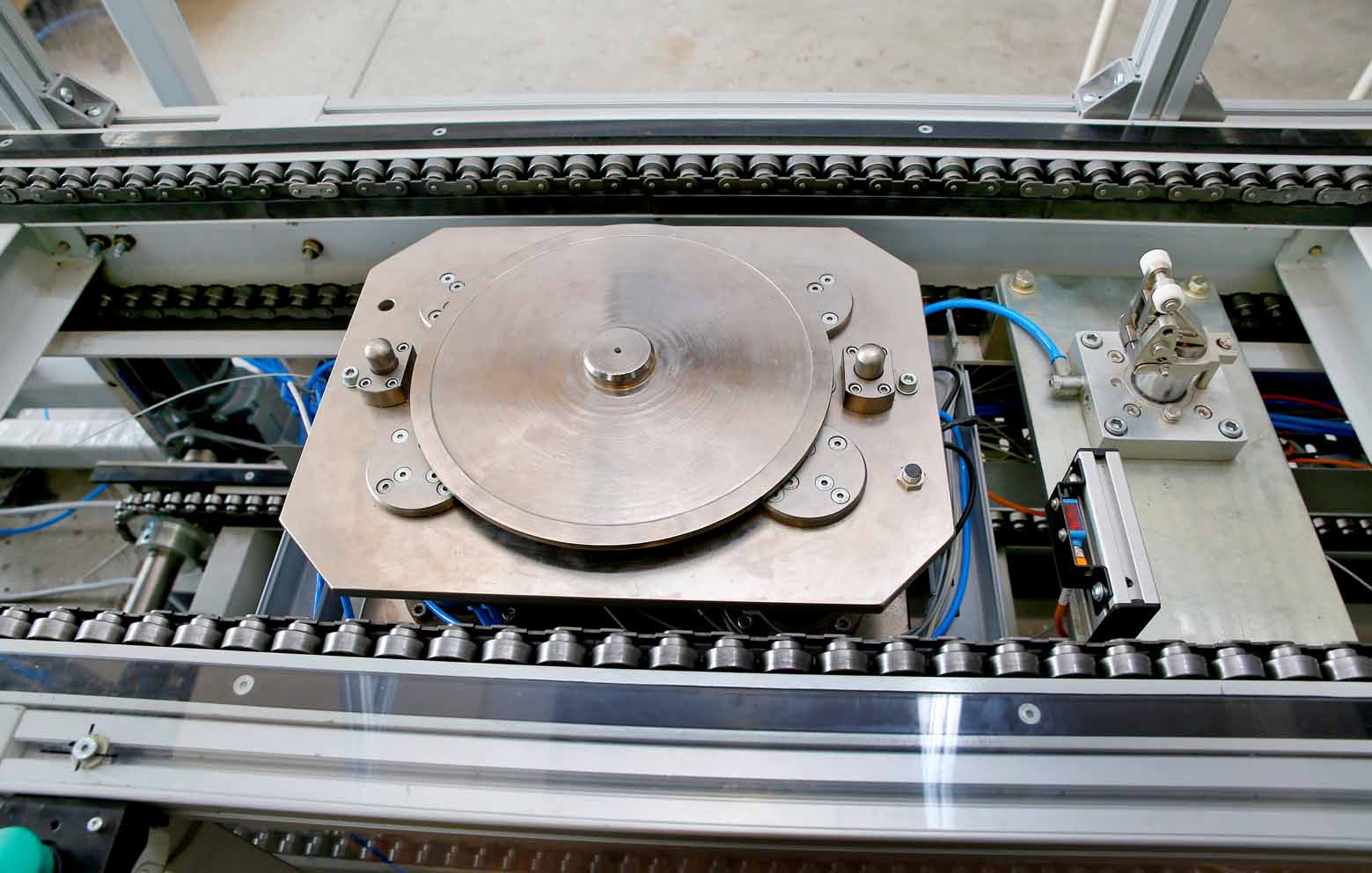

Pallet Conveyors are used to carry individual parts between assembly stations, machining centers and to other stations. Such conveyors are built using endless chains or endless belts on which the pallet is carried.

Each part is seated on a custom designed pallet, ensuring that the orientation of the part remains constant at all times. The pallets move on the conveyor asynchronously, and can buffer (or accumulate) prior to entering a workstation, or after exiting a workstation.

Various sensors and pneumatic stoppers are integrated with the control system that communicate with each station and ensure that the pallets are released just in time for the operator / automatic station to receive them. Pallets can also be RFID or Barcode tagged to ensure track and trace of the assembly operations.

Lifter stations and rotating stations can be incorporated within the conveyor line enabling the parts to be handled as per the custom requirement.

- Accumulation Pallet Conveyors

- 90 Degree Transfer / Shunts

- Pallet Lift Mechanism

- Pallet Lift & Rotate Mechanism